Frenzelit: Today’s innovations for tomorrow’s world

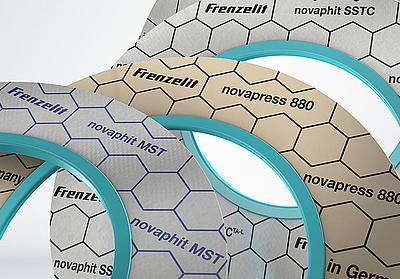

Whether you are looking for a proven product or an individually tailored solution: Frenzelit will find the optimal combination of material and functionality for you. We convert highly functional gasket materials and technical textiles into gaskets and insulation that you can rely on, even in the most demanding applications. Our expansion joints are created as tailor-made components for system engineering. And we offer a portfolio of innovate composite materials with hicoTEC® products.

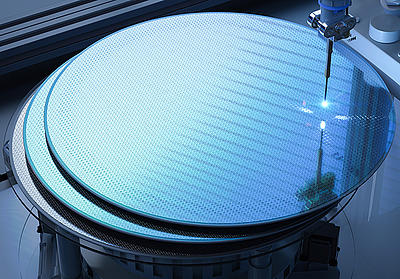

Our products are used throughout the industry and mobility sectors, as well as in the essential future fields of hydrogen technology, e-mobility, fire protection and renewable energies. We use the production and industry knowledge of over 600 employees and the expertise gained over the past 140 years to work constantly on innovations – so that you can profit from our in-depth product expertise and service.

Special requests? Product idea?

Global presence

We have a global network of subsidiaries, sales, service and logistics partners in over 65 countries around the world.